Pre-treatment - pre-sorting, shredding and drying

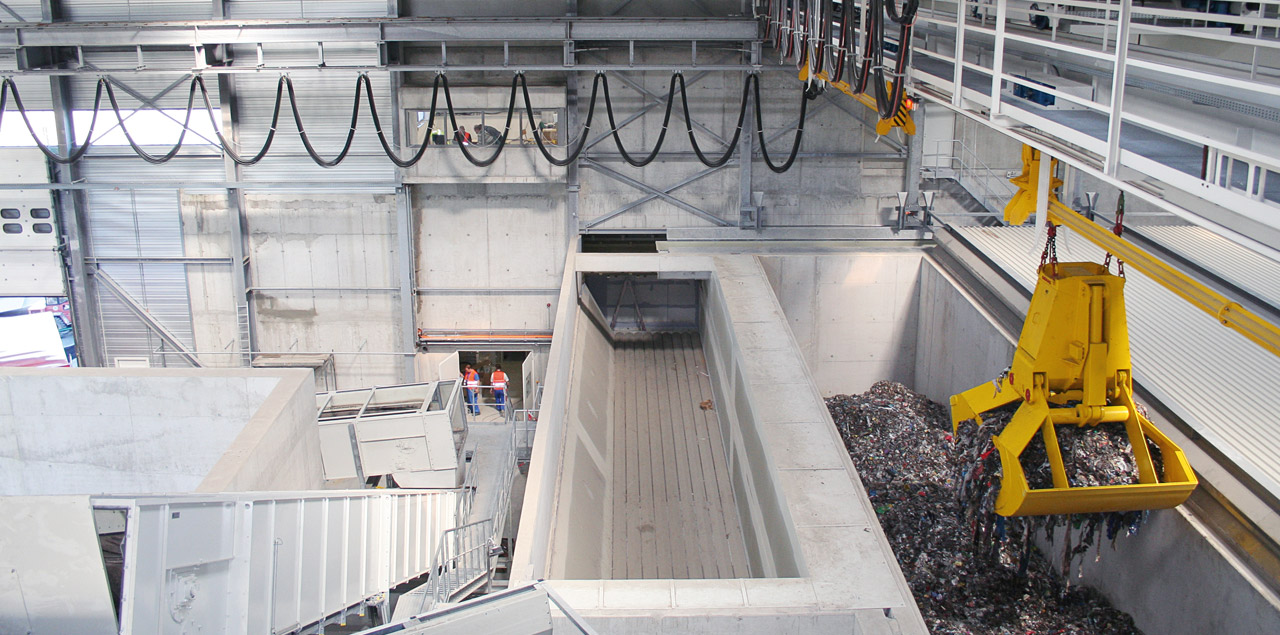

The moist waste is emptied into a deep silo. Its capacity of about 7,000 m3 is equal to about 300 truck loads.

In a separate area, the flat silo, bulky waste and dry industrial waste are roughly separated, shredded and then processed. For instance the wood is separated from the bulky waste and immediately transported to biomass power plants for energy recovery.

Upholstered furniture and mattresses are shredded and then added to the residential waste in the deep silo. The industrial waste is partially used for the production of a substitute fuel (RDF) which can be used in specific RDF power plants without passing through the whole MBS.

Pre-chopping

The waste from the silo is put on two parallel working shredders by a computer-operated crane. After this pre-chopping to a particle size of about 250 mm the waste is transported into a concrete intermediate silo. A second computerized crane takes the material from the silo and places it into one of the nine ‘rotting boxes’.

Dehydrating process

In the ‘rotting boxes’ the first important step for the processing of the waste is effected. For separating and sorting the waste must be dried. The micro organisms contained in the garbage produce heat which leads to the evaporation of the moisture. The waste is stabilized biologically. Computer-controlled air supply and exhaust ventilators regulate the temperature level and divert exhaust and moisture from the boxes. The loss of the moisture leads to the loss of approximately 30% of the waste’s mass. This dehydrating process takes approximately seven days.

Exhaust air

The exhaust created by the dehydrating process cannot simply be released to the outside. At 50 ° C, it contains organic compounds such as alcohols and aldehydes as well as aromatic hydrocarbons, which form odorous substances.

By condensing the exhaust in a heat exchanger the moisture is eliminated. The revolving condensate is treated separately: In water treatment concentrations of ammonium, COD and BOD5 are reduced as in a sewage treatment plant. The water is then filtered. The clean wastewater partly evaporates in the cooling circuit.

The exhaust air dehydrated in the heat exchanger is now purified in an air treatment system. According to legal requirements of the 30th Federal Emission Regulation, the gaseous materials contained in the air are thermally destructed at about 850 ° C before the air is released through a chimney into the environment.

Measuring devices in the chimney permanently record the concentrations of dust, nitrous oxide and organic matter. In this way the compliance with prescriptive limits is continuously monitored. All data is stored and once a year an emissions report is handed over to the state environmental agency. The data are also published in official journals and on this site.