Energy management - because it pays off

Management systems in general mean quite a lot of effort for small organisations like the ZAB with regard to documentation. There is no separate personnel department which is only concerned with this. Nevertheless, the association has had a regularly certified energy management system according to DIN EN ISO 50001 since 2012.

For many energy-intensive companies in the manufacturing industry, energy management is the norm. They benefit from special compensation regulations for the electricity price. For example, a significantly lower EEG levy and a lower electricity tax are payable. A special-purpose association such as the ZAB cannot benefit from such financial advantages because, as a special-purpose association, it is not assigned to the manufacturing industry.

The high expenditure for energy management pays off - for all

In order to produce high-quality substitute fuel (RDF) for industrial power and cement plants, a high level of technical effort is required. Many machines for the processing of the waste mean a lot of electrical energy is needed. In order to protect the environment and avoid harmful emissions of gases, the exhaust air is thermally cleaned, which means a high consumption of natural gas. The ZAB had correspondingly high energy costs.

Our aim is to make waste treatment, which also affects the wallets of the inhabitants of the association's area, as cost-effective as possible. Therefore, we have considered how we can use less energy and still carry out our waste treatment with the same quality.

Energy efficiency

This is the technical term around which all energy management revolves. The association set out to increase its energy efficiency. The longest path begins with the first step, and in our case that meant measuring. At home, the meter only shows the electrical work (kWh). In an industrial plant, the electrical work (kW) is also measured and it is also a separate component of the electricity price, as the plant is not connected to the low voltage grid but to the medium voltage grid. In addition, there are many subordinate internal meters that measure work and power of the main consumers.

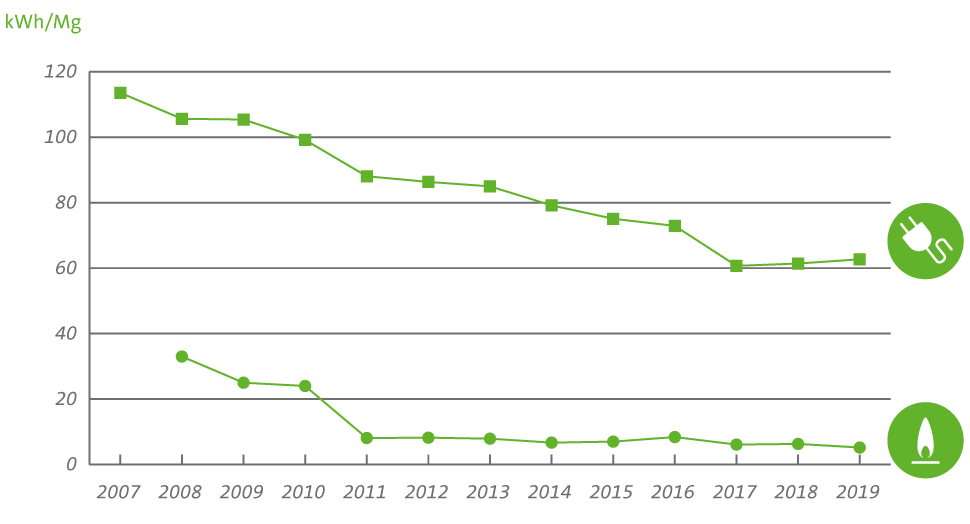

To visualize the energy consumption, a software programme was written for the ZAB in cooperation with a programmer, which helped us to optimize the processes of waste treatment. This can be seen particularly well in the curve of the specific gas consumption for exhaust air purification. The specific consumptions of electricity, gas and fuel are our key figures. Specific in this case means how much electricity, gas and fuel we need to treat one ton of waste. Improving these figures as continuously as possible is the core of our energy management.