The Procedure

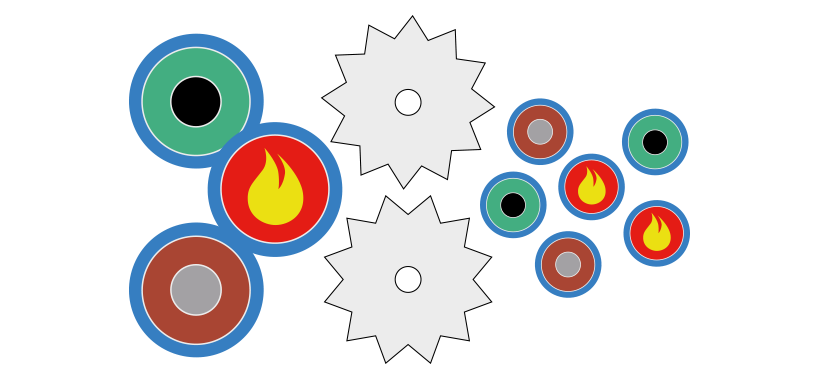

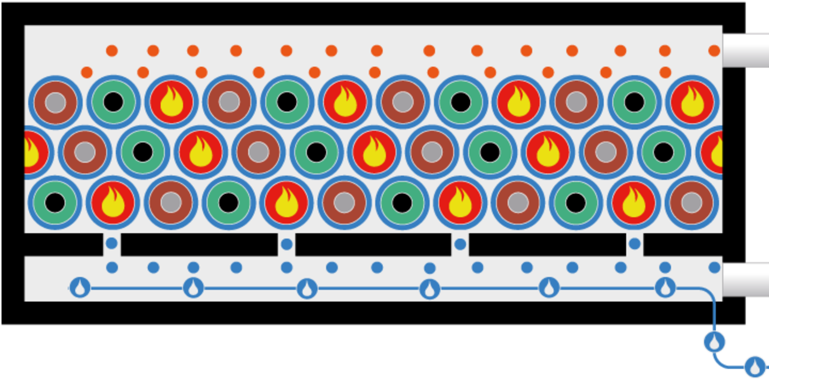

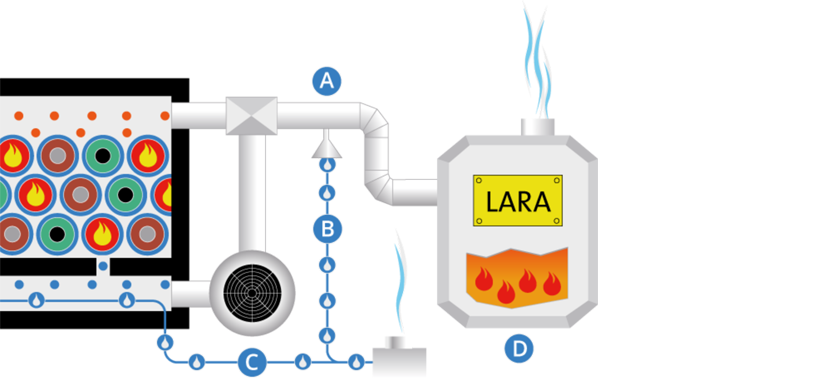

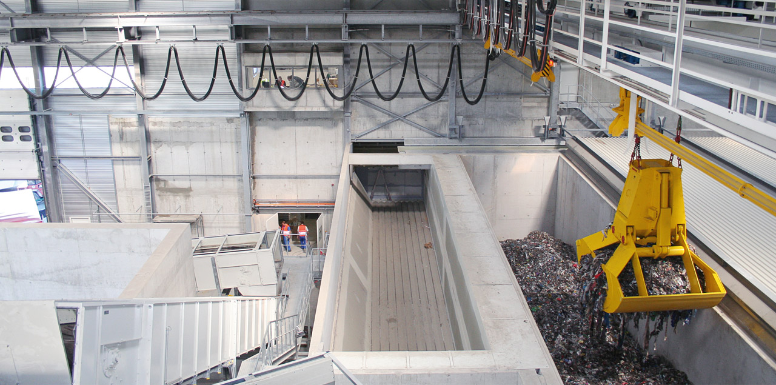

The mechanical-biological stabilisation plant (MBS) of the ZAB works according to the Herhof dry stabilate process®. The basic principle of this process is the biological drying of the waste using heat generated by the microorganisms contained in the waste.

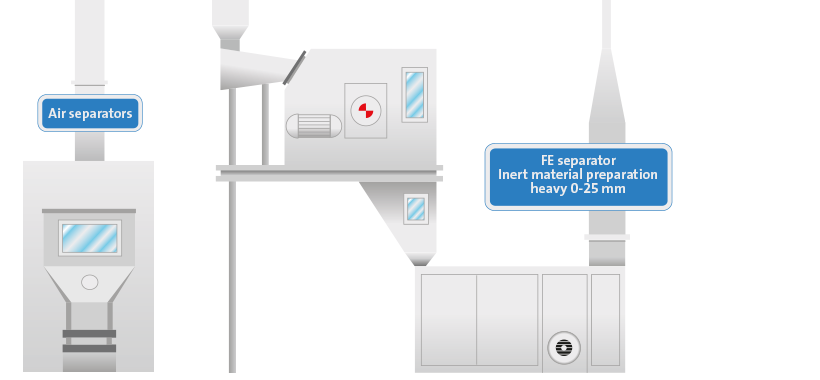

The dry waste is then mechanically processed. In several stages the combustible components are separated from metals and inert components (stones, sand, glass, and ceramics). The then-produced refuse derived fuel (RDF) is energetically used in lignite-fired power plants and the cement industry.

Ready-made to measure

With the Stabilat® process waste is processed by mechanical-biological treatment in ways that large parts of the components may be intelligently re-used as secondary raw materials. Combustible waste materials are specifically processed to high-class industrial fuel and are used instead of oil or coal in the cement industry and in power plants. The fuel is converted and tailored to the client’s needs. Therefore it is either slightly pelletized in a pellet press or produced as a pellet.

Valuable ferrous and nonferrous metals such as aluminium and copper as well as batteries are regained and can be recycled

Environmentally sound and complete

The method implemented by ZAB proves that waste no longer needs to be a problem for the environment. Specific treatment of waste into products is possible and worthwhile. It allows for maximum flexibility in waste disposal, guarantees a stabilisation of waste management costs and looking to the future solves the question of landfilling. Thus scarce natural resources can be protected and the burden on the environment eased.